Transmission Repaired and Re-installed!

Blogpost written by Bob

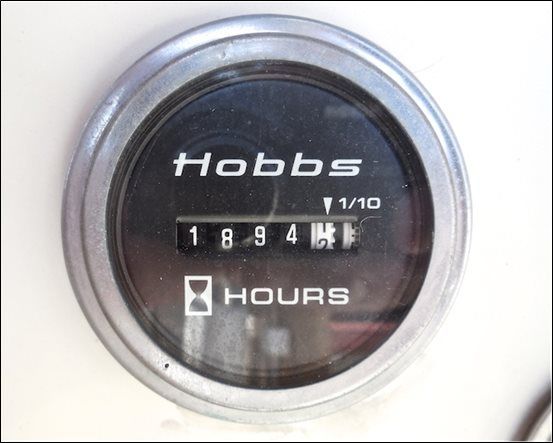

As it turns out I'm glad we chose the rebuild option and Terry Kivett of Hartge Yacht Harbor to do the repair work. With a 1500-hour service life expectancy until a rebuild, a new transmission would have been simply more expensive with very little additional benefit. The used transmission (one of the three options) had 1500 hours of service and it probably would have needed a rebuild very soon--this option would have been a complete waste of money. There's no doubt in my mind that we made the right decision.

|

| The total cost of the transmission repair was just under $1500 and the boat was out of service for about 3 weeks. Fortunately, the repair was completed just in time for our month-long sailing trip. |

Manual Bilge Pump Rebuild

The manual bilge pump is a back up pump to the electric bilge pump. It is a matter of safety to keep this pump operational. I had to remove the pump in order to rebuild it. Two of the six stainless steel mounting bolts were corroded in the the aluminum pump housing and could not be removed. I had to drill them out from the cockpit using titanium drill bits and my very heavy-duty drill. Once they were drilled out, I still couldn't remove the pump! Eventually, I got it out--the two bolts I drilled the heads off were stuck in the aluminum pump housing and wouldn't easily pull from the fiberglass. I was able to remove the two stuck bolts from the pump housing by using a vise-grip pliers and simply twisting them out--I then enlarged the holes in the pump housing with a drill so this couldn't happen again.

The ingenious design of the Whale pump allows it to be oriented in two different directions through the placement of two bolts. The original installation in my boat never took advantage of this design and, instead, the lines were snaked around backward to suit the orientation that the pump probably shipped in from Whale. Wanting a more streamlined installation, I took advantage of this design feature and made the pump inlet connection closest to the bilge and the pump outlet connection closest to the overboard discharge fitting.

When I reinstalled the manual bilge pump after the rebuild it worked fine. So, it was either the debris in the pump and/or the old rubber seals were bad.

Recently Completed Small Projects

|

| Fixing the engine kill switch was simply a matter of an adjustment at the connection to the engine. Apparently, this mishap occurred when the motor mounts were replaced early this spring. |

|

| Our work to restore a rowing dinghy has taken a lot of our time during the recent two weeks. |

We now have 57 projects on the "to do" list and 92 projects on the "completed" list--about two thirds done. On the eve of our month-long sailing vacation I feel a lot better about my list of projects now that the transmission is fixed but many of the remaining projects are the most expensive ones.

Our next blogpost will be after the first week of a month-long cruise on the Chesapeake Bay. We may be so relaxed and disconnected that we forget about making a blogpost or we may kill each other. Stay tuned...

Thanks for following our blog!

No comments:

Post a Comment