Improving Deck Drains

--Blogpost written by Bob

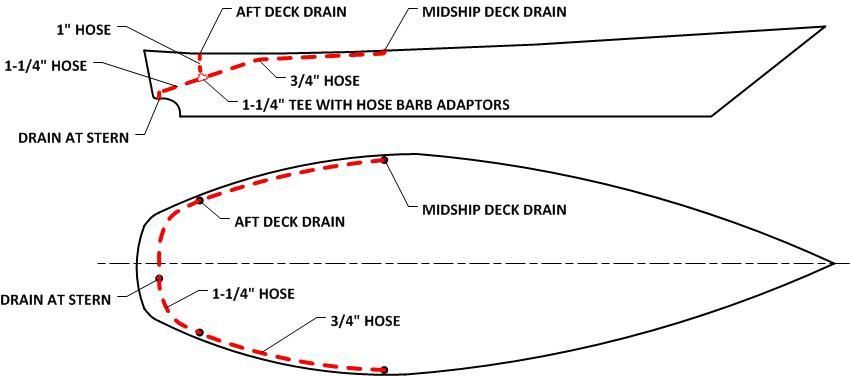

On the C&C Landfall 38 there are four deck drains, two at midship and two a few feet forward of the stern. Originally, all the deck drains had plastic deck fittings that connected to 1/2-inch hoses. The two aft deck drains were routed to a single tee mounted on a small thru hull fitting (about 3/4-inch) that was slightly above the waterline at the stern just to port of the boat's centerline. The two midship deck drains were directed into the bilge--so, when it rained, the bilge accumulated a lot of rainwater unless the bilge pump transferred it overboard. In my opinion, this was a design flaw by C&C. In the event of a failure of an automatic bilge pump (which were not supplied as original equipment), a heavy rain could cause internal water damage to the vessel.

In addition to this design flaw, during the early years of my love affair with s/v Rainy Days (there's no other way to describe it!) I noticed that the deck drains would regularly become blocked. Most of the time it was due to a collection of (helicopter) seeds from nearby maple trees--these seeds were just the right size to block a 1/2-inch deck drain.

The solution I developed for my boat was made incrementally over several years of trying things and then making modifications. I ended up with a system that no longer experiences blockage and all the rainwater drains overboard the way it should. This system has been in place on my boat for the past 15 years and I'm posting it here so that other Landfall 38 owners can benefit from my experience.

Enlarged Deck Fittings

First, I enlarged the deck drain fittings as large as I could--I was restricted by the size of the troughs that were built into the deck. I increased the midship deck drain fittings to 3/4-inch and the aft deck drain fittings to 1-inch. (Long after the increase in sizes, I changed all the deck fittings from plastic to stainless steel.)

Enlarged Hoses & Rerouting

I ran a 3/4-inch hose from the midship drain fitting to the plastic tee that is about 12 inches below the 1-inch diameter aft deck drain fitting. This resulted in a 125 percent (for the midship drains) and a 300 percent (for the aft drains) increase in flow area compared to the original 1/2-inch diameter hoses used on both drains. It is surprising how such small increases in hose diameter can make such huge increases in flow area.

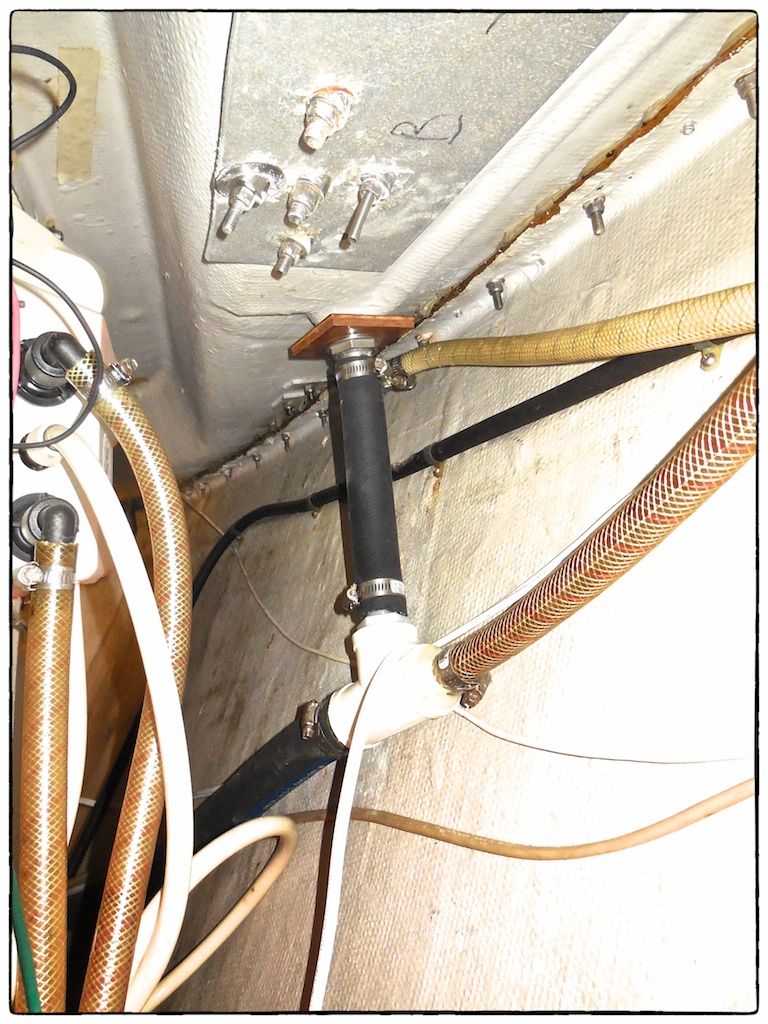

The aft deck drain fitting ties into a 1-1/4-inch plastic tee where the drain hose size increases to 1-1/4-inch diameter. Hose barb adaptor fittings are used to adapt to the three different sizes of hoses that come together at this tee.

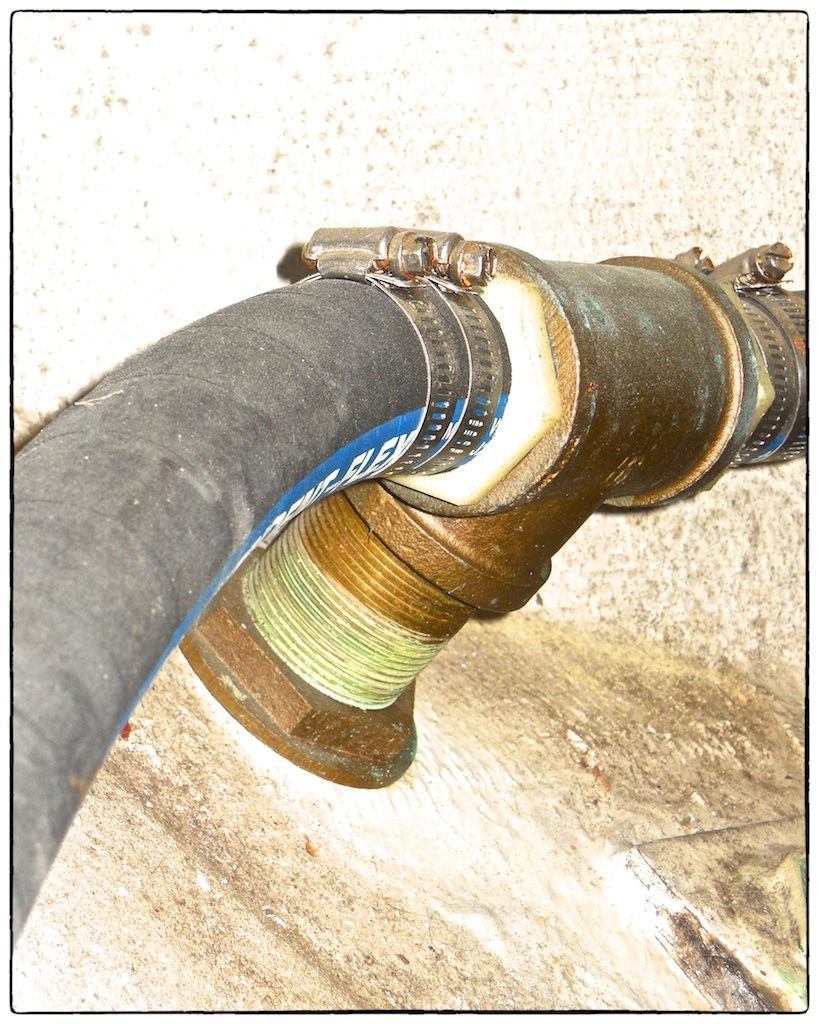

The 1-1/4-inch hoses from each side of the boat join together in a bronze tee that is mounted to a new 1-1/2-inch bronze thru hull fitting that is located just above the waterline just to starboard of the centerline of the boat. (I'm using the original 3/4-inch thru hull fitting intended for the deck drains for discharging warmed water from my air conditioner.) All the hoses run at a generous and uniform slope to promote good drainage toward the dedicated hull fitting at the stern. All hoses and fittings in this system are above the boat's waterline.

|

The four deck drains are connected with increasingly larger hoses as the drained water moves aft and the ultimately drain through a 1-1/2-inch thru hull in the stern |

Summary

The largest expense associated with this project was having a new 1-1/2-inch bronze thru hull installed at the stern--this had to be done during a haulout. (Another option to having a dedicated 1-1/2-inch thru hull is to tie the deck drains into the 1-1/2-inch cockpit drain hoses.) The hoses and fittings were relatively inexpensive until I changed all the deck drain fittings to stainless steel. This system has proved advantageous during the winter when rainwater in the bilge would freeze and prevent the bilge pump from doing its job.

This is our 100th blogpost and our blog now has over 7,000 page views, thanks to all the readers of our blog! Recently we've experienced a glitch that is not distributing newly published posts to subscribers but we'll figure it out and fix it.

Next up will be my do-over for the spaghetti wires...

Thanks for following our blog!

No comments:

Post a Comment