From Wedding Dresses

to Jerry Jug Covers?

--Blogpost written by Maggie

After making

the cover for the table in the cockpit, I realized that my current sewing

machine (used to make numerous wedding dresses as a side business) was not suitable for sewing boat canvas projects. In January I ordered an Ultrafeed LSZ-1 and

Tenera thread from Sailrite.

One of the most challenging parts of this whole project (making covers for our four jerry jugs stored on deck) was adjusting to the new sewing machine and learning to sew using Tenera (a type of Teflon) thread. The advantage of Tenera thread is that it does not degrade when exposed to sun and water as polyester does. My first attempt with the new

machine and thread resulted in multiple skipped stitches and broken thread.

After wasting lots of time trying to fix the problem myself, I called Sailrite

for advice and watched the tutorial video they provide on their website.

I made the suggested adjustments and had success. Some of the adjustments I made were:

(1) Making a spool holder (from a plastic milk jug and a knitting needle) that allowed the thread to come off the spool horizontally thus eliminating the twists that resulted in thread breakage.

(2) Adjusting the upper tension all the way down and then tightening it incrementally until I was satisfied with the stitch quality.

I made the suggested adjustments and had success. Some of the adjustments I made were:

(1) Making a spool holder (from a plastic milk jug and a knitting needle) that allowed the thread to come off the spool horizontally thus eliminating the twists that resulted in thread breakage.

|

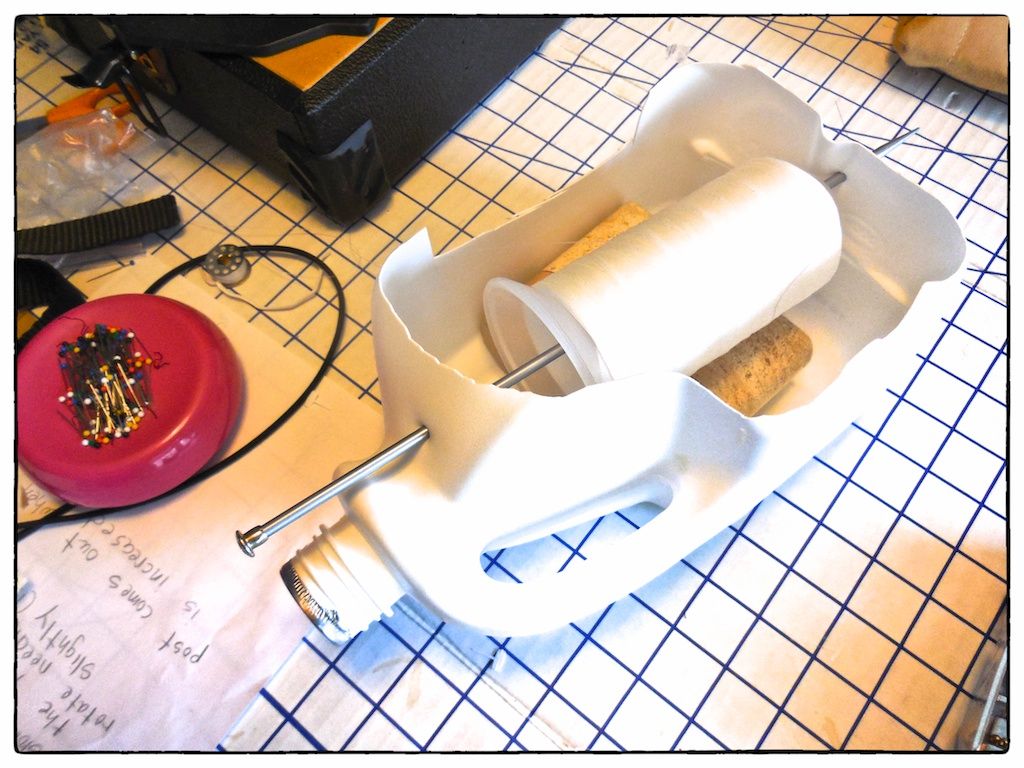

| This is my horizontal spool holder (made from a plastic milk jug). I was anxious to complete the project and used materials I had on hand (the milk jug and the knitting needle). |

(2) Adjusting the upper tension all the way down and then tightening it incrementally until I was satisfied with the stitch quality.

After solving the machine and thread problems, I started the project by designing a cover using scrap material I had on hand. The cover needed to have holes strategically placed to allow the straps (that attached the jerry jugs to the supports) to fit through easily.

|

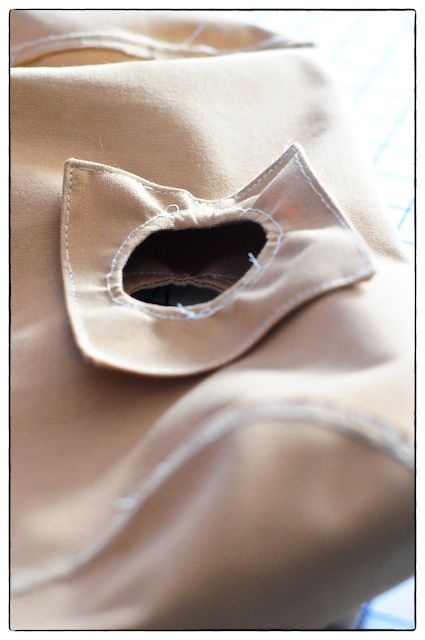

| This photograph shows how I designed the holes that the straps go through. I reinforced the inside of the holes to prevent abrasion damage from the straps rubbing the fabric. |

They also

needed a casing at the bottom to thread shock cord through to keep the covers

tightly in place.

|

| We used a shock cord crimping tool and stainless steel hog rings (made specifically for connecting shock cord) to connect the ends of the shock cord in the bottom of the cover. |

I then took the prototype I designed apart and used it as a pattern for the four jerry jug covers. I constructed them out of marine quality Sunbrella fabric in a color (toast) that matched the table cover I made previously. After I finished one cover, Bob and I put it on the jug and attached it to the supports Bob had previously made and attached to the stanchions.

|

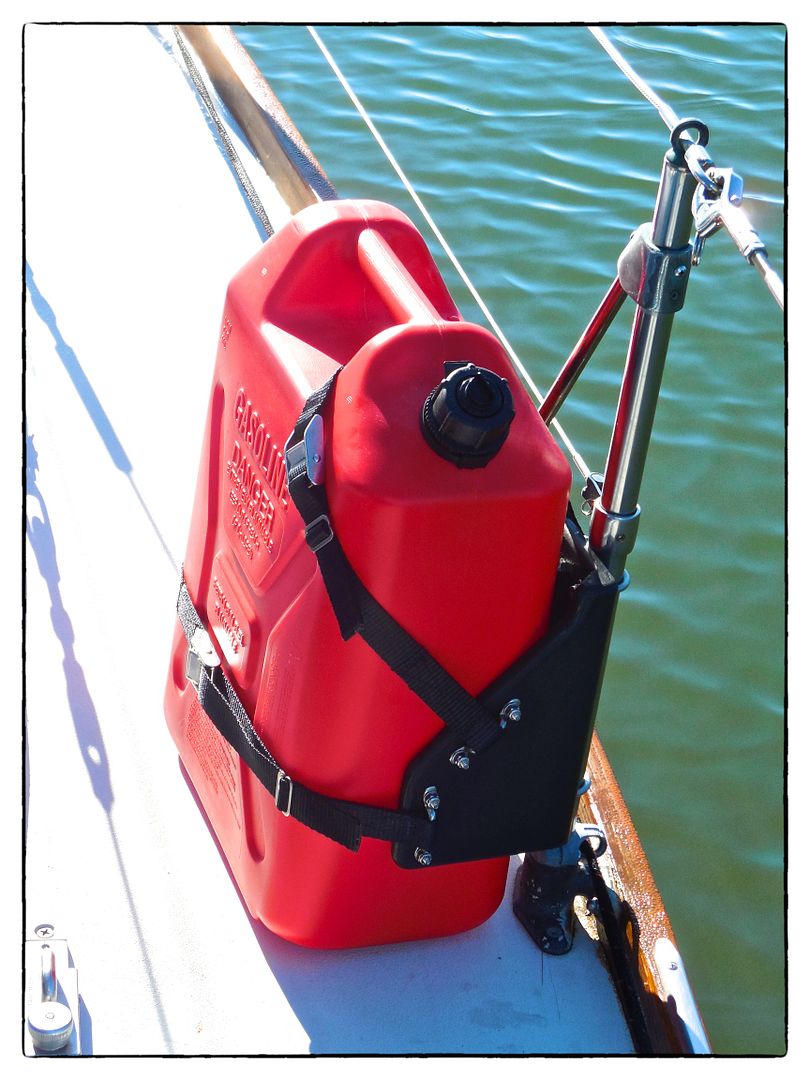

| This shows a jerry jug in place without the cover and with the original stainless steel buckles. The stainless steel buckles were difficult to use and we changed to plastic buckles. |

|

| The above image represents the first trial run of a new cover mounted on a jerry jug in the supports. |

We decided to replace the stainless steel buckles with black plastic parachute buckles (both from strapworks.com). They may not last as long as the stainless steel buckles, but are much easier to

handle. The worst part of that job was

removing the stainless steel buckles since they were sewn on so expertly (by Marty's Bag Works) with

Tenera thread. I broke two seam rippers

in the process.

|

| All the effort paid off. I think they look pretty good, don't you? |

The

approximate cost for this project:

· Thread - $115.00 (of course I’ll use

this on future projects too.)

· Fabric - $55.00

· Webbing - $10:00

· Buckles - $15.00

Thank you

for reading our blog!

Covers look great.

ReplyDelete