Windlass Installation - Part 1

--Blogpost written by Bob

A few weeks ago we jumped on a good deal for a windlass (Maxwell RC8-8) for our boat--it was recommended by another member of the C&C forum, Paul Eugenio of s/v Johanna Rose. We had the new windlass shipped directly to the boatyard we selected to do the installation, Hartge's Yacht Yard in Galesville, Maryland.

Because of the way the windlass was designed (with the chain to the anchor on the right side of the chain exit into the anchor locker) we decided to reverse the positions of our two anchors, placing the new Rocna, our primary anchor, on the port side of the bow. We changed the rode for this anchor to an all-chain (G-4 grade) rode that is 225 feet long.

The secondary anchor is our 44-lb Bruce--it is now mounted on the starboard side of the bow. For our Bruce anchor, that we will lift manually, we attached our old rope/chain rode from the previous primary anchor system since it was the newest one of the two. We don't expect to use the secondary anchor very often but we have it mounted for when we need it.

One of our anchor rollers was best suited to a chain rode--we switched this (grooved) roller to the port side of the bow for use with the all chain rode.

|

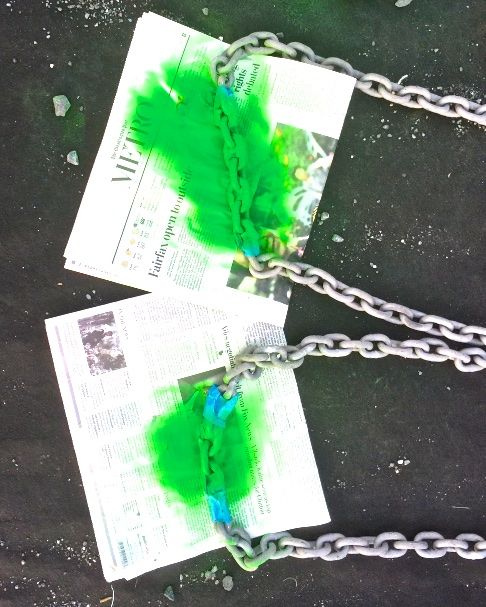

| We taped off areas on the chain to create painted bands using fluorescent green paint. |

|

| The hole for the windlass motor was reinforced with a heavy piece of solid (red) fiberglass sheet below the boat's deck--this was intended to distribute loads from the windlass. |

As it stands right now, the windlass is completely installed but in testing the windlass with the chain before departing, the chain piled up on itself right up to the chain exit from the windlass. So, we have to modify the anchor locker to be deeper than it is right now and kick the chain pile forward with a sloping plate. As soon as we solve this issue we will be on our way back to Baltimore. Stay tuned for Part 2 as we solve the problem of the chain piling up on itself.

Thanks for following our blog!

No comments:

Post a Comment